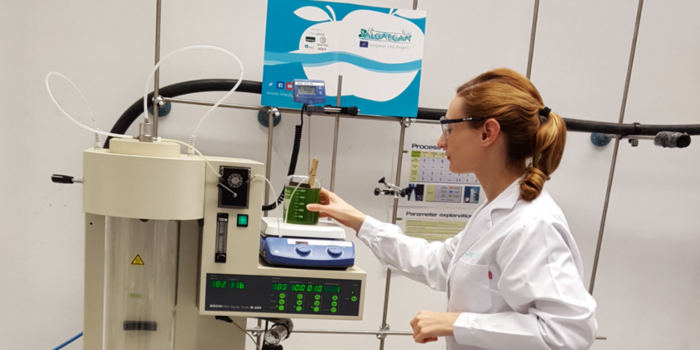

CARTIF researchers carry out the first laboratory tests of the LIFE Algaecan project with the spray dryer, to know the operating conditions of the drying of microalgae, the microorganisms with which this project works to carry out the water treatment residuals from the fruit and vegetable processing industry.

These tests have been carried out at different inlet temperatures and inlet flow percentages to find the best option with the highest microalgae powder extraction performance.

The technology developed in this project will allow, on the one hand, to reduce the cost of fruit and vegetable processing and, on the other, to eliminate the environmental impact associated with the generation of waste in the form of sludge, as happens with traditional aerobic treatment systems and your usual landfill deposit. In addition, this development will allow obtaining high-quality effluents that can be reused for irrigation or cleaning or discharged into channels.